- Wireless horizontal splicing machine

- Longitudinal seamless splicing machine

- Veneer Edge Trimmer

- Two end veneer cutting machine

- Veneer leveler

- Conveying equipment

- Double cutter

- Veneer press

- To undertake the splicing of wood and leather

Product description

The finisher is the optimum equipment to solve the problems of wrapping,wrinking and roughness caused by sliced veneer and single board and other factors that affect product quality.The machine features unique design,leading process and low energy consumption.Improvement is made based on leading technology.The PLC automatic control is adopted.The sliced veneer to be finished is delivered by conveyor to the veneer finisher.Different pressure,temperature and time are set,depending on the tree variety,for heat pressing and cold pressing finishing.The veneer is automatically output upon finishing,which can satisfy the requirement of veneer finishing.The machine is characterized by leading design,low energy consumption,high efficiency,reliable performance and convenience for operation and maintenance.Throungh experiments,the veneer for many tree varieties upon finishing can achieve the best finishing effect.The veneer will not rebound after finishing,which abviously improve the original value of veneer.The product is a pioneer in China.With such product,the day of rough veneer will end forever.

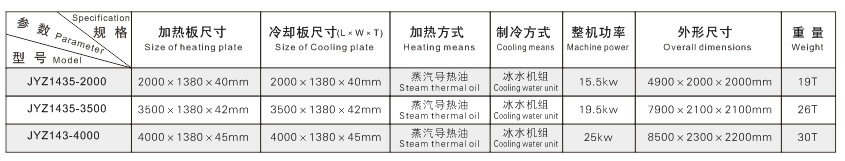

Technical parameter